Rings

HAND MADE TITANIUM RINGS AND WEDDING BANDS

HAND CUT - HAND SHAPED - HAND GROUND - HAND POLISHED

CUSTOM MADE FOR YOU TO YOUR EXACT SIZE

Click on photos above to display various Rings

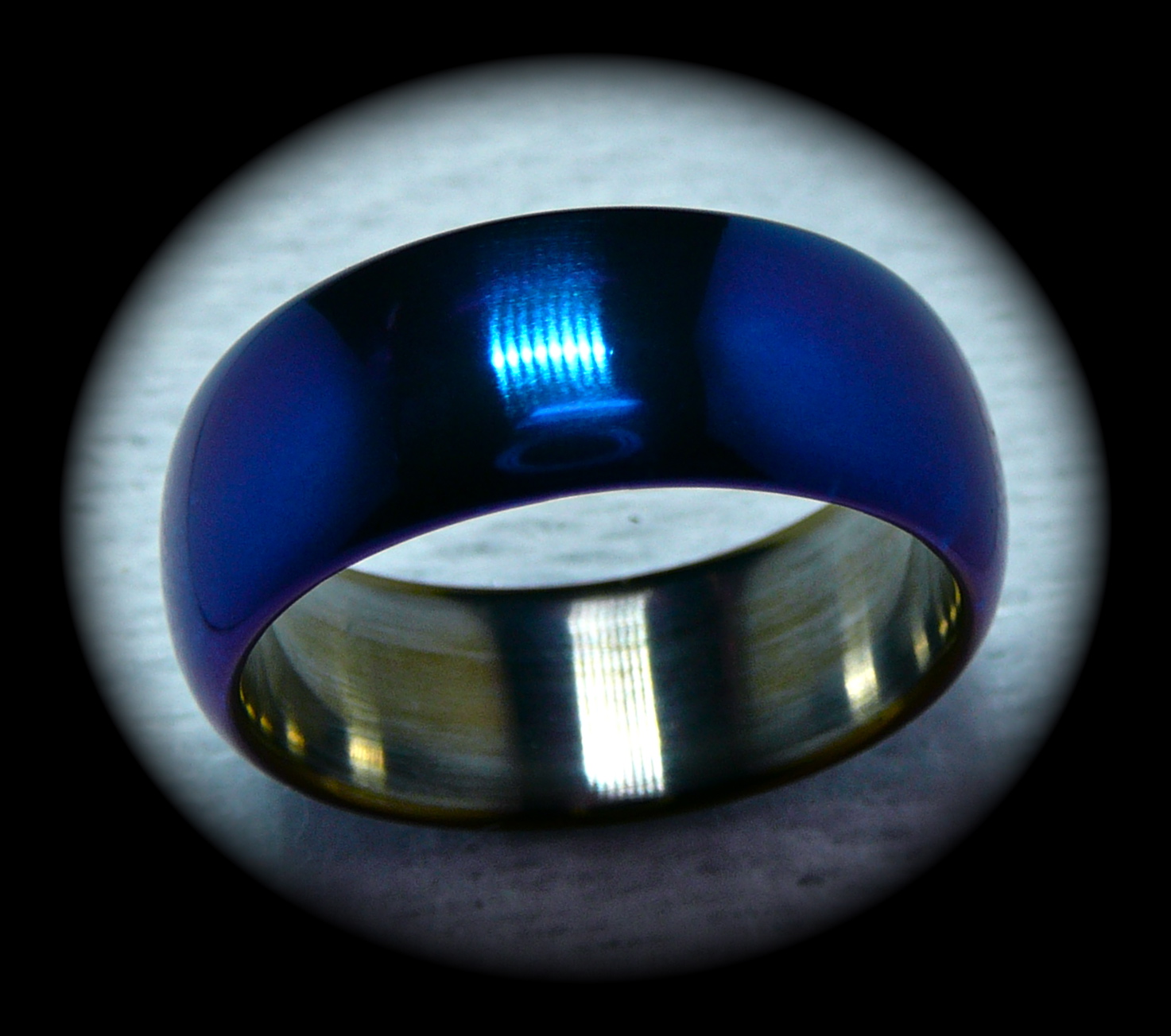

Rounded Style Rings

Widths 0.200” to 1/2 —

Widths Under 1/8" to 0.200” —

Made of a solid part of titanium that is cut from a mission flown part of the SR-71 Blackbird.

These rings are not made using automated machine tools or metal lathes.

During the forging process, each ring is carefully hand formed around a custom made sizing die at 1000 degrees

The ends are welded using the Tungsten Inert Argon Gas method and then hand ground and polished to the final size and profile.

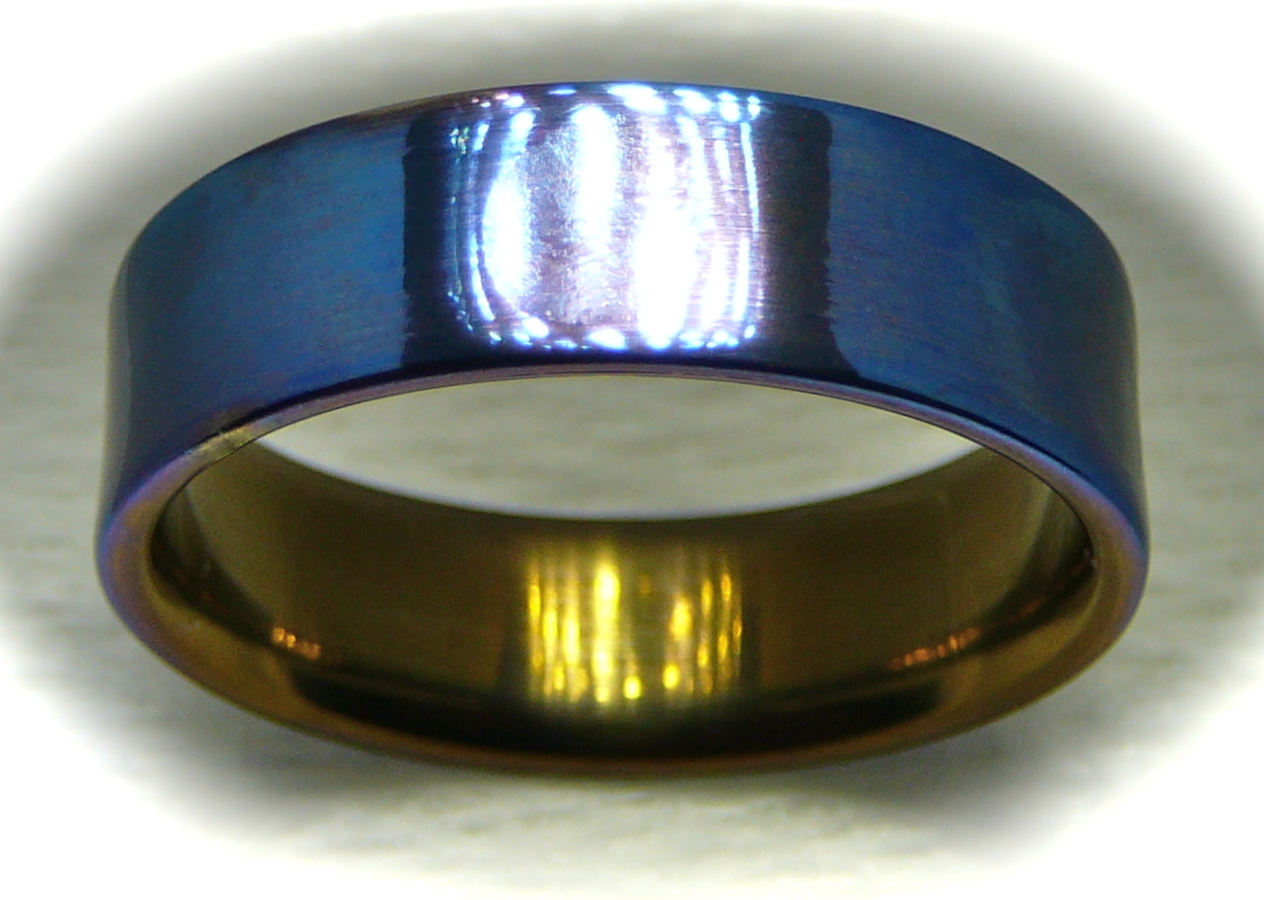

Polished 3/8" Mission Flown Oxidized

High Polish

1/8" Small

1/4" Edge of Space

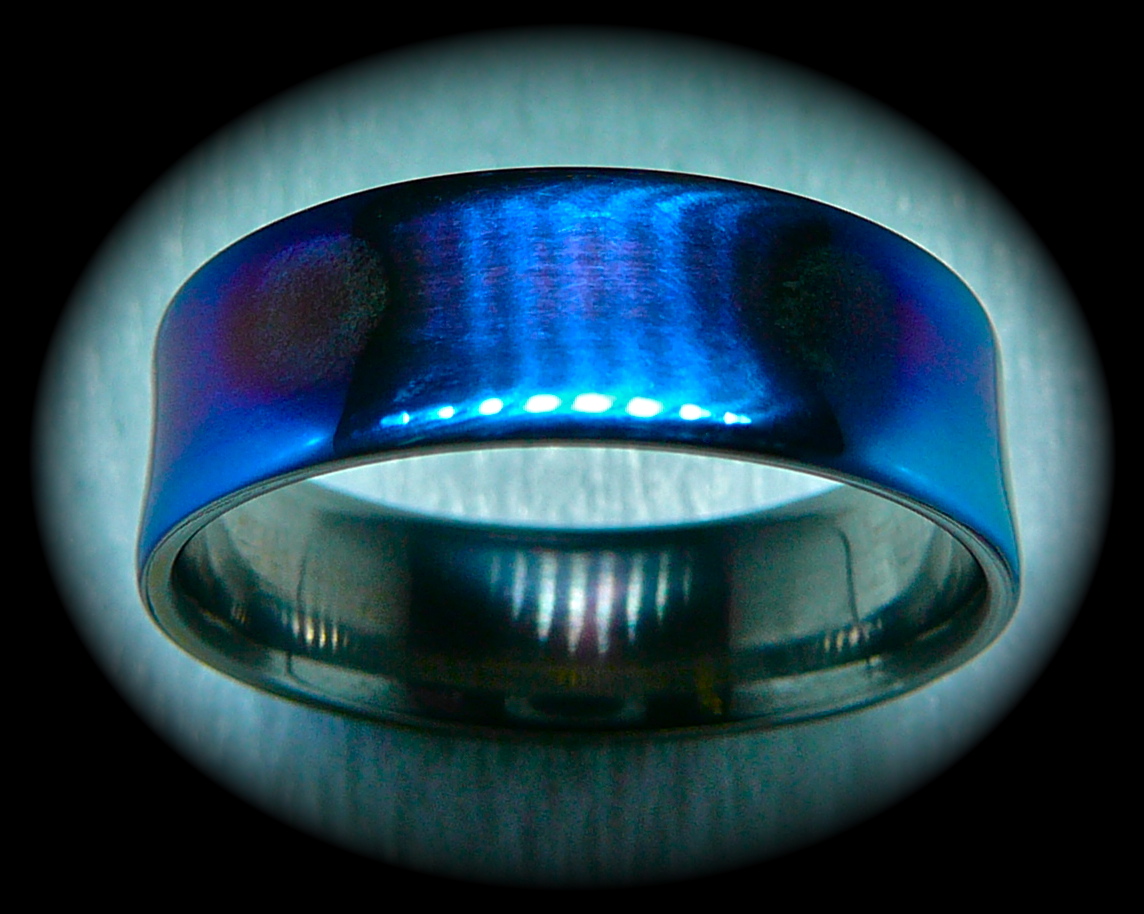

Low Profile Rings

Widths to 1/4" to 5/16" —

Composed from a part which has two layers of the SR-71 Titanium metal.

These rings display a feature presenting a texture unique to every individual ring.

Polished Colorized

Variable Colorized in the Satin Finish

Polished Original Titanium Hue

You choose the Surface Finish and Coloring.

Surface Finish --- Polished or Satin

Colors --- Original Titanium Hue, Edge of Space, or Mission Flown Oxidized

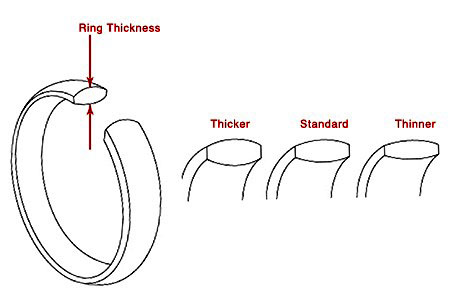

I offer three general choices in thickness.

Thicker

Depending on the width and size I will make the ring bulkier.

Standard

I will select the best thickness, based on the width and size for a perfect balance between the look and comfort.

Thinner

Depending on the width and size I will make the ring as thin as possible.

This is a photo of one of the parts that my rings are created from. These Titanium ejector nozzle parts controlled and contained the tremendous heat and thrust that pushed the Blackbirds faster than a speeding bullet.

All photos are only examples of items produced using the SR-71 mission flown titanium.

Items are hand made, no two items are alike nor can they be reproduced or duplicated in the exact likeness.

I will try to achieve the requested colors, shapes, and appearance but all can vary slightly.

The extreme conditions in which these parts were operated has a variable affect on the finished product. Operating at 3,200 degrees F with pressures exceeding 34,000 pounds per square inch, along with the tremendous earth shaking vibrations at the SR-71 exhaust afterburner that propelled the 120,000 pound aircraft faster than a high powered rifle bullet.

It's simple to understand how these conditions affect the metallurgical structure of the titanium metal as well as being hand made. This is why the finished items including rings will all be unique in appearance.

You design your own ring !

Includes a personalized Certificate with all the details as well as a Fact Sheet.

FREE- USPS PRIORITY Shipping in the U.S.

Note: All metals and finishes can be scratched when abraded.

Titanium is much harder than gold or silver.

The finish and coloring effect surface hardness. The darker the color the more durable the surface.

All rings are rounded on the inside diameter for a comfortable fit.